Excel through innovation is one of our core values. We create new methods, deliver new technologies and come up with innovative solutions to provide endless stream of values to our customers.

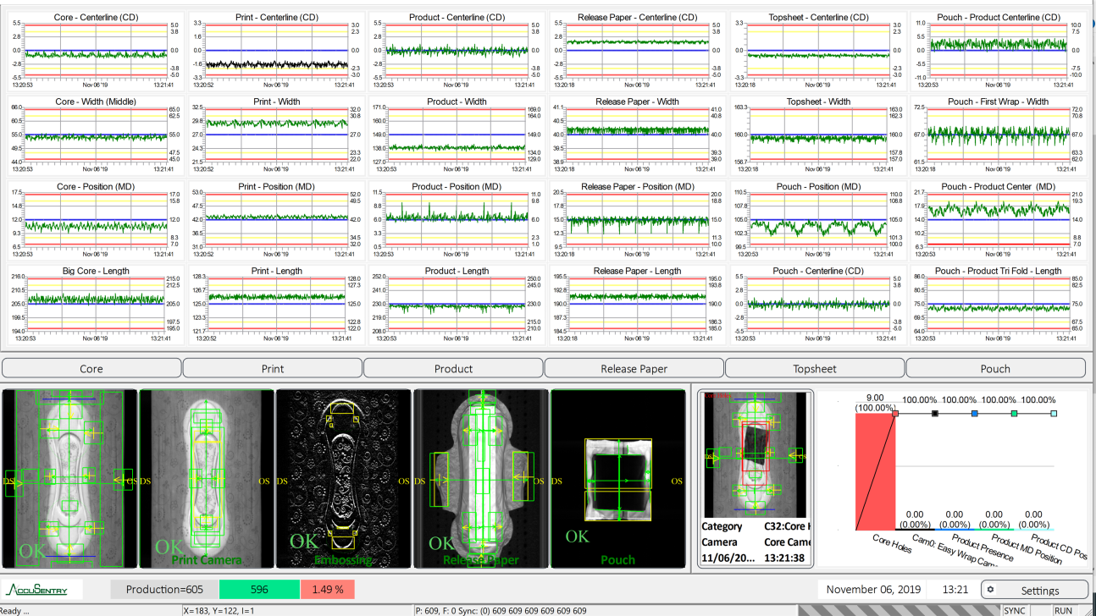

SentryDash is a dashboard of normalized graphs to instantly convey key centerlining measures and capability of production process in real time. The technology fosters a culture of engagement by empowering the operators to take quick actions to steer the production process to targets.

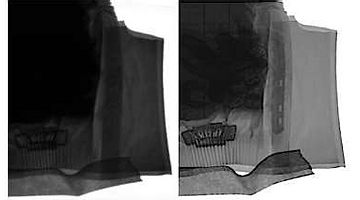

Crystal image significantly enhances the product image clarity to achieve robust inspection. This technology enables our customers to inspect product components with very subtle contrast. Combined with our powerful and advanced image processing algorithms, we ensure the accuracy and reliability of the inspection.

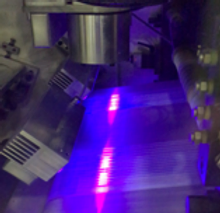

Multiple Lighting Technology simultaneously captures distinct images with a single camera using various lighting techniques. By fusing the images from different lighting techniques, we are able to address challenging applications that are otherwise impossible to inspect.

As production lines get faster, the timing required to control the reject gate is getting increasingly more challenging. Our system monitors the reject gate and precisely adjusts the reject signal based on product size and cutting knife timing. Unlike typical vision systems which reject 3-5 products, AccuSentry system only rejects one product for each defect detected, a waste reduction of 66%-80%.

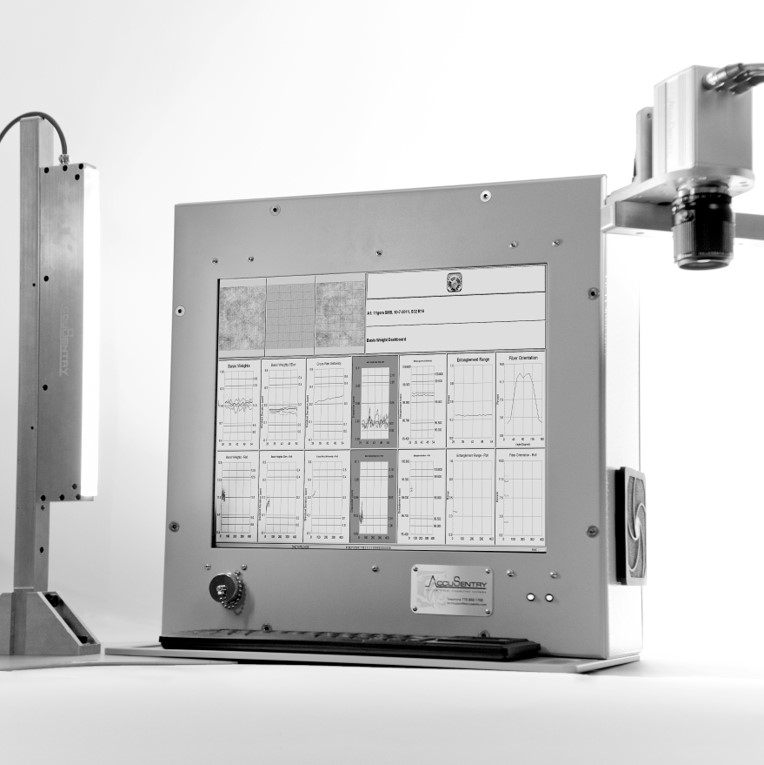

Our hardware and software technologies are seamlessly integrated with advanced image processing algorithms to deliver a versatile platform for our customers. The platform provides an inspection framework with a customizable HMI (Human Machine Interface) to address challenging inspection applications and adapt to varying operational requirements.

Learn More