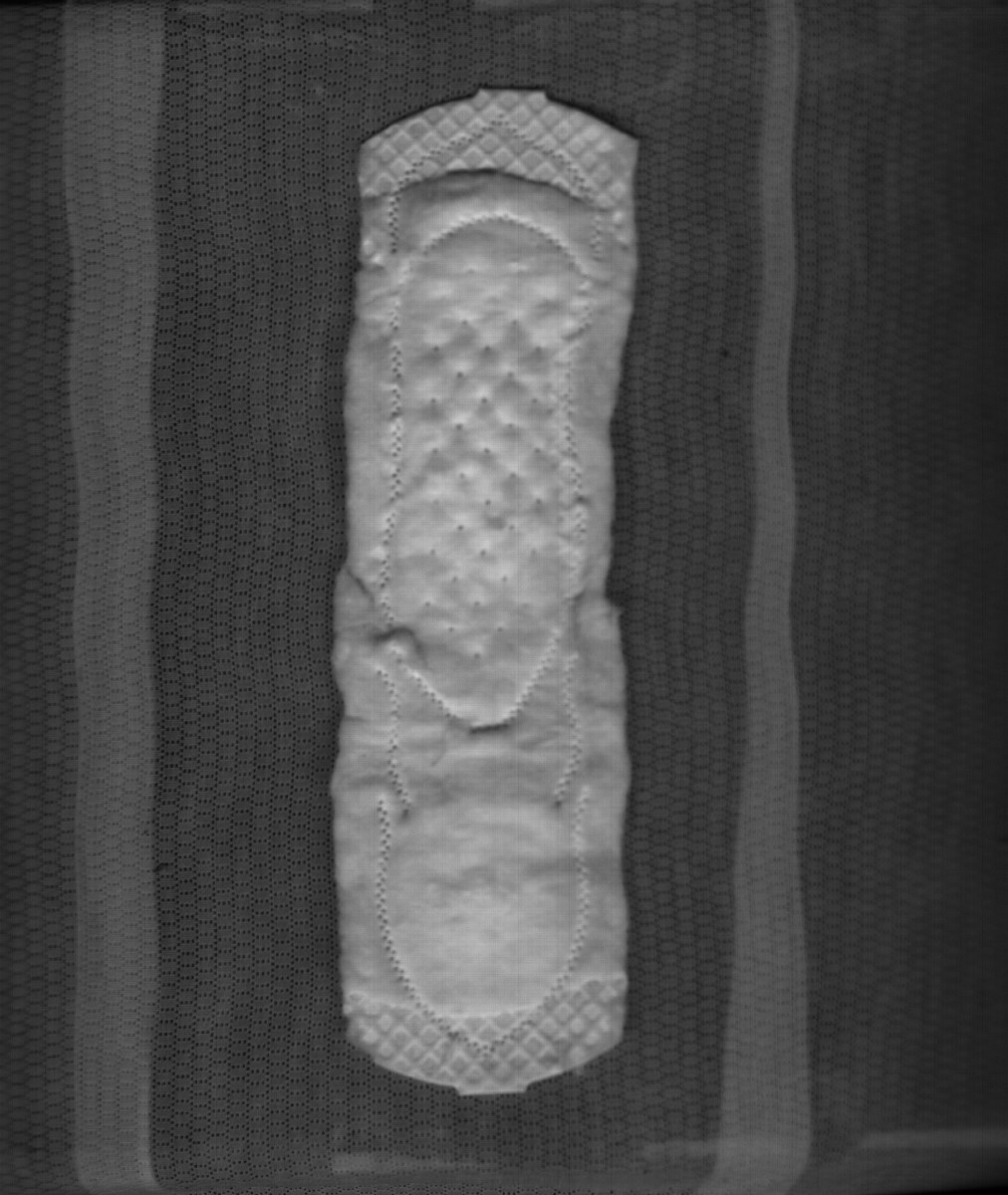

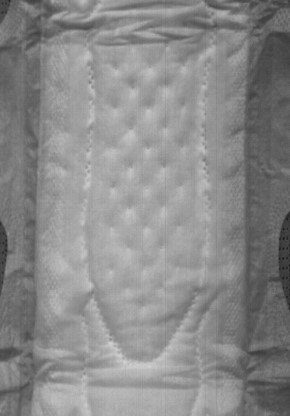

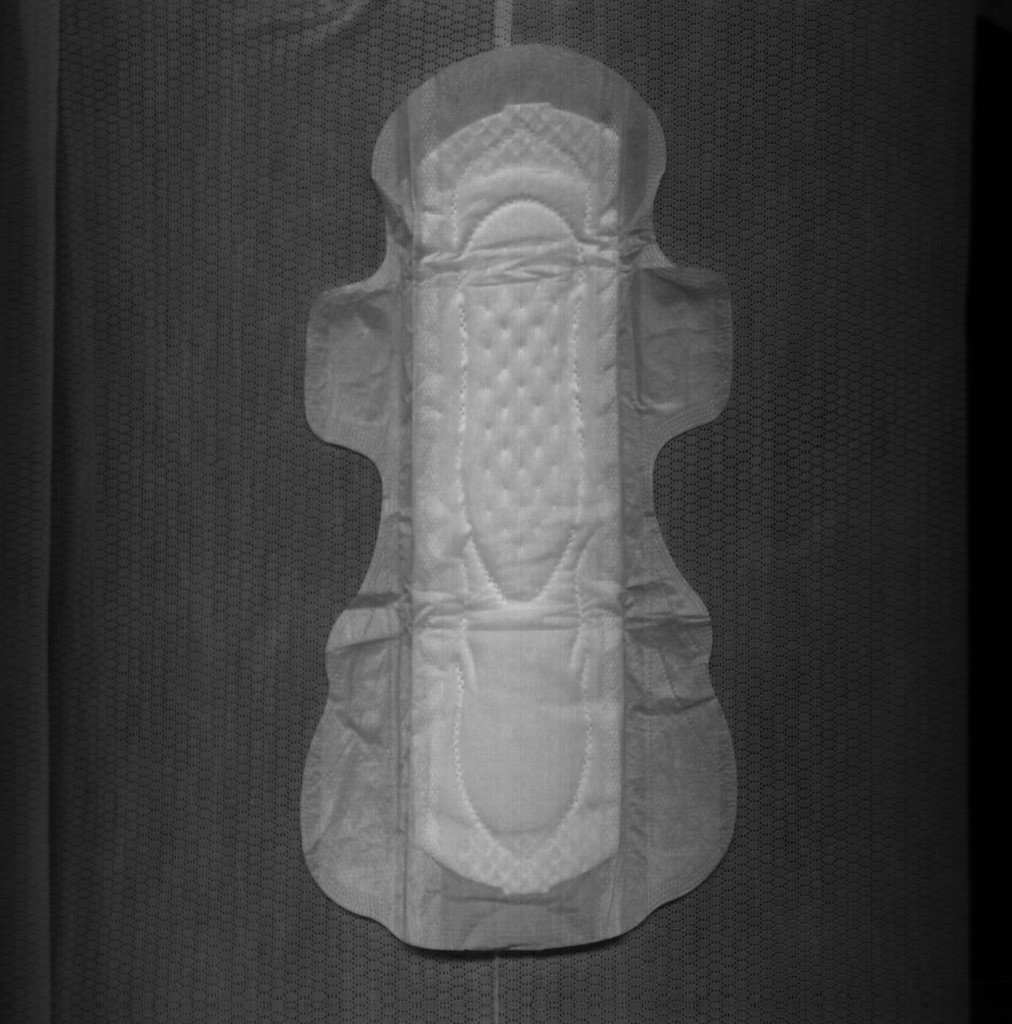

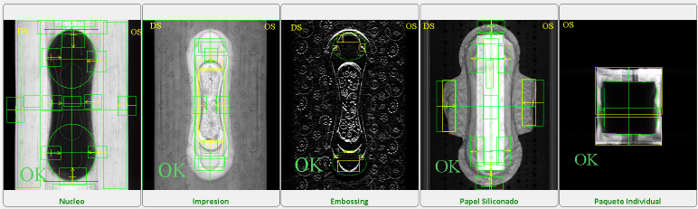

AccuSentry helps Sanitary Napkin and Feminine Pad manufacturers improve their quality control and increase production efficiency via our SentryDash and Sentry 9000 camera technologies. Sentrydash helps you run your machine at higher performance levels with an easy-to-understand dashboard based on six sigma methodologies. Sentry 9000 is our machine vision inspection software which accurately inspects each product inline. Together, SentryDash and Sentry 9000 help everyone from the operator to the plant manager understand key product measurements and use them to control the process, leading to increased quality, increased efficiency, and reduced waste. For many of our customers, efficiency has increased by more than 5% and waste has declined by at least 0.5%!